Issues in your semi-truck lighting can turn routine operations into big problems for fleet managers and owner-operators. Whether you’re dealing with burned-out bulbs, flickering lights, or complete electrical failures, these issues compromise safety and regulatory compliance on the road.

The good news is that most lighting problems have solutions that are easy to implement with the right knowledge and approach. Explore the solutions for common semi-truck lighting problems in this guide, and keep your fleet running safely and legally.

Combat Corrosion With Preventative Measures

Corrosion attacks electrical connections and metal components, leading to poor electrical contact and eventual failure. Apply specialized anti-corrosion treatments to connectors, terminals, and mounting hardware in high-risk areas. Road salt, moisture, and environmental contaminants accelerate corrosion, particularly in coastal regions or areas with harsh winter conditions.

Using stainless steel or specially coated hardware provides superior resistance to corrosive elements. Preventative corrosion control extends component life and reduces the frequency of electrical repairs and replacements.

Inspect and Replace Faulty Bulbs Regularly

Regular bulb inspection forms the foundation of any effective lighting maintenance program. Check all lighting components during your routine pre-trip inspections, looking for complete failures or visible damage to the bulb housing.

When you discover faulty bulbs, replace them immediately rather than postponing the repair. Doing this prevents minor issues from becoming major safety hazards. Keep a complete set of spare bulbs in your truck or maintenance facility to address problems quickly without waiting for parts orders.

Fix Dim or Flickering Lights

Dim or flickering lights typically indicate electrical connection problems that require immediate attention. Examine all wiring connections for looseness, corrosion, or physical damage that could interrupt the electrical flow. Tightening loose connections often resolves flickering issues, while corroded terminals need cleaning with an appropriate electrical contact cleaner.

Frayed or damaged wiring needs repairs or replacement to restore electrical continuity and prevent further deterioration. Address these electrical issues promptly to maintain consistent lighting performance and avoid the safety risks associated with unreliable illumination.

Prevent Water Damage to Lighting Systems

Water infiltration causes expensive damage to electrical components and creates ongoing reliability problems. Inspect all lighting fixtures regularly, and seal lenses, gaskets, and mounting points. Replacing worn or cracked seals prevents moisture from entering sensitive electrical areas where it may cause shorts or corrosion.

High-quality waterproof lighting provides long-term protection against environmental exposure. Water-resistant designs maintain electrical integrity even in harsh weather conditions, reducing the frequency of repairs and component replacements.

Upgrade to LED Lighting for Better Performance

LED technology offers advantages over traditional incandescent bulbs in terms of brightness, energy consumption, and longevity. LEDs improve visibility while reducing the electrical load on your truck’s charging system. Commercial-grade LEDs withstand vibration, temperature extremes, and physical impact better than conventional bulbs.

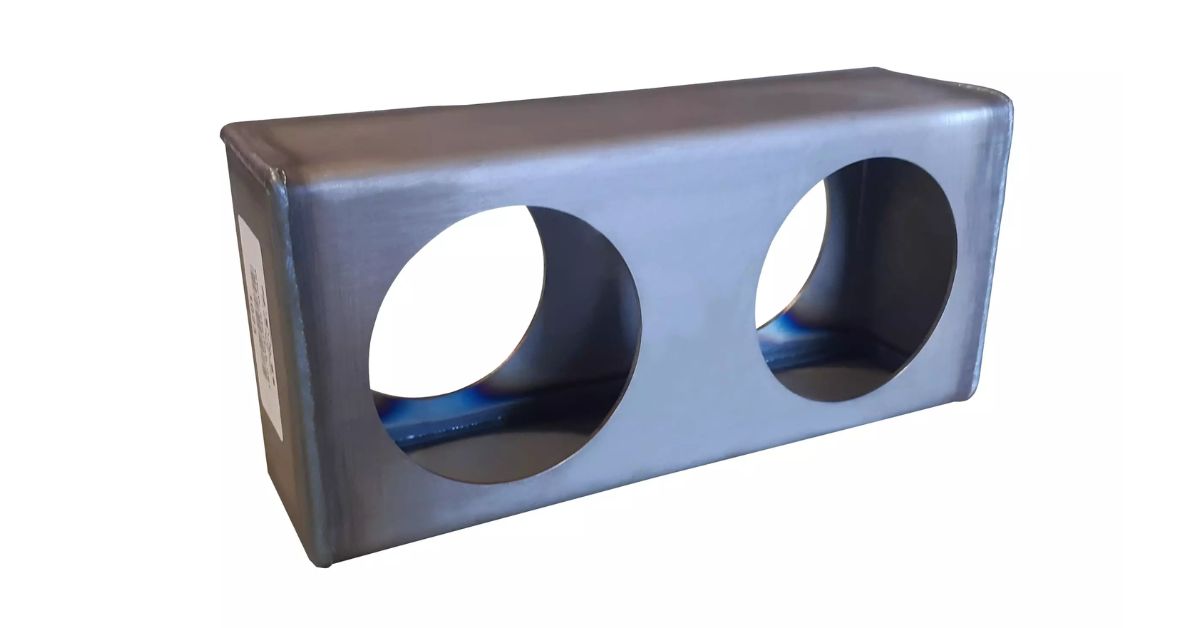

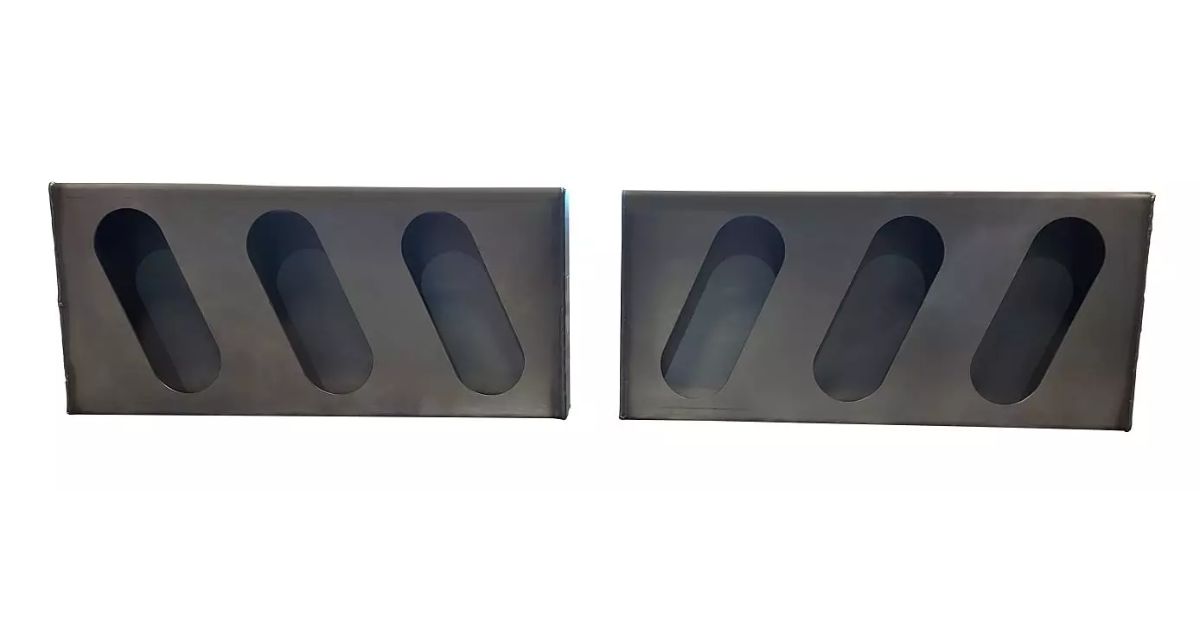

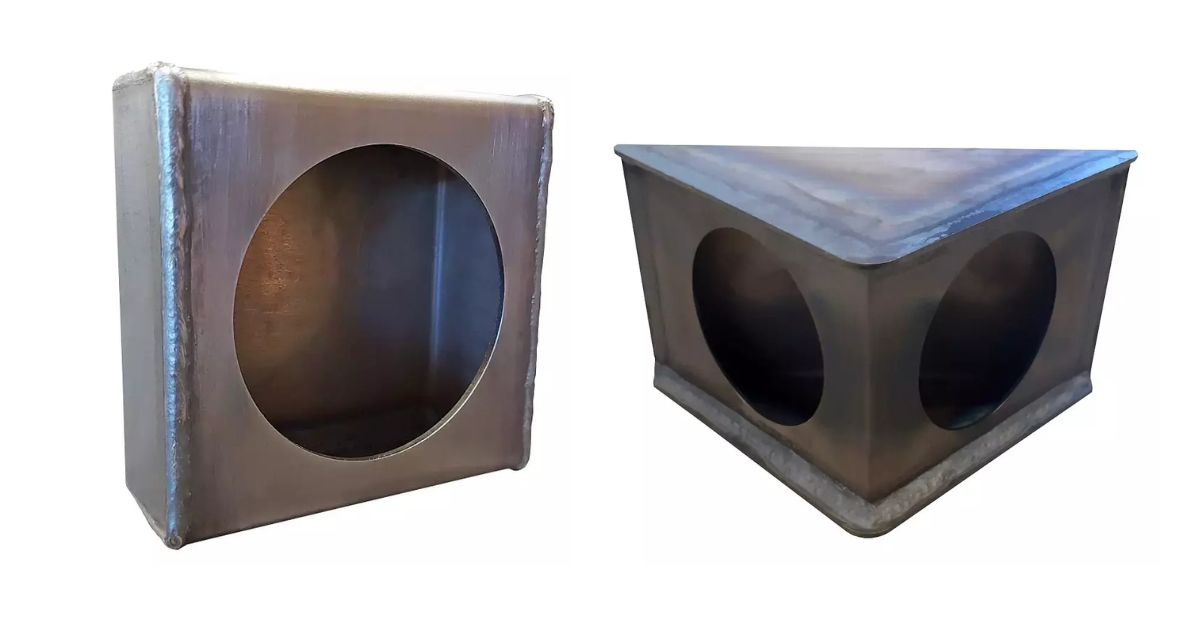

Truck tail light boxes equipped with LED technology provide exceptional durability and performance that meet the demanding requirements of commercial transportation. These upgrades typically pay for themselves through reduced replacement costs and improved fuel economy from lower electrical demands.

Check Electrical System Compatibility Before Installation

Compatibility issues between new lighting components and existing electrical systems cause frequent installation problems. Verify voltage requirements, wattage specifications, and connector types before purchasing replacement parts or upgrades.

Many modern lighting systems require specific electrical characteristics to function properly and avoid damage to sensitive components. Use appropriate adapters or wiring harnesses for integration with your truck’s wiring.

Confirm compatibility beforehand to avoid costly returns, installation delays, and potential damage to expensive electrical components. If you are unsure about the compatibility between components, the professionals at Star Fabrication are here to help you determine the specs and requirements.

Inspect Wiring for Hidden Issues

Wiring problems often develop in areas obscured during routine inspections. Examine all accessible wiring for signs of wear, chafing, pest damage, or corrosion that could lead to electrical failures. Pay special attention to areas where wires pass through metal openings or contact moving parts that could cause abrasion over time.

A solution for semi-truck lighting problems, such as protecting vulnerable wiring with appropriate conduit or protective sleeves, prevents unexpected malfunctions. Regular wiring inspections help you identify potential problems before they cause complete lighting system failures or create safety hazards.

Enhance Visibility With Reflective Accessories

Reflective materials supplement your lighting system by providing passive visibility enhancement that works without electrical power. Strategic placement of reflective materials creates a comprehensive visibility system that exceeds basic regulatory requirements and enhances overall road safety. Apply high-quality reflective tape to strategic locations on your trailer to improve nighttime visibility for other drivers.

Reflective markers and accessories integrate seamlessly with existing lighting systems to provide additional safety benefits. These passive safety measures remain effective even when electrical systems fail, providing a backup visibility solution.

Simplify Troubleshooting

Signal and brake light malfunctions create serious safety risks and regulatory violations that require immediate attention. Reduce troubleshooting time by using plug-and-play lighting assemblies that eliminate complex wiring connections. Regular functional testing of all signal and brake lights should be part of your standard pre-trip inspection routine.

Quick-connect systems allow for faster diagnosis and repair when problems occur on the road. Systematic testing procedures help you identify whether problems originate in the lights themselves, the wiring, or the truck’s electrical system.

Use Smart Lighting Solutions

Advanced lighting systems include diagnostic capabilities that simplify problem identification and reduce troubleshooting time. Modern diagnostic features help you maintain higher reliability while reducing maintenance costs and downtime.

Monitor lighting system health in real-time with intelligent components that provide status information and failure notifications. These smart systems often include built-in protection against voltage fluctuations and electrical anomalies that damage conventional lighting. Connected lighting networks alert you to problems before they cause complete system failures or safety violations.

Create a Proactive Maintenance Plan

Systematic maintenance prevents most lighting problems before they occur and reduces emergency repair situations. Establish regular inspection schedules that include cleaning, testing, and component replacement based on operating conditions and manufacturer recommendations. Driver training programs help with identifying potential problems during daily operations, allowing for immediate attention to prevent bigger issues.

Maintenance checklists encourage you to pay attention to all lighting system components and track component performance over time. Proactive maintenance approaches cost less than reactive repairs and provide better safety and compliance outcomes.

Stay Updated on Compliance Standards

Lighting regulations change periodically, and staying current prevents expensive violations and legal problems. Monitor FMCSA updates and state-specific requirements that affect your lighting system specifications and performance standards. Regular compliance reviews help you identify areas where your equipment may need updates or modifications to meet current standards.

Work with knowledgeable suppliers, such as Star Fabrication, to receive components that meet the latest regulatory requirements. Compliance management protects your operation from fines while ensuring your equipment provides the safety performance that regulations intend to achieve.

Effective lighting system management requires consistent attention, quality components, and proactive maintenance practices that prevent problems before they affect your operations. When you implement these strategies, you reduce downtime, improve safety, and maintain regulatory compliance. Take action today by assessing your current lighting systems and identifying areas where these solutions will improve your fleet’s performance and reliability.

No comments yet.