Every professional hauler knows that securing cargo is just the beginning. Once you’ve strapped down your load with chain binders, where do those heavy tools go? Tossing them into the cab or trailer bed creates clutter, risks damage, and wastes precious time on your next job. Load binder hangers solve this problem by keeping your equipment organized, accessible, and ready when you need it most.

Choosing the right load binder hanger means considering your specific hauling needs, the weight of your equipment, and how you want to access your tools on the road. The right rack system keeps your workflow smooth and your trailer exterior clean. Let’s explore what makes a quality load binder hanger and how to select one that will serve you for years to come.

What Are Load Binder Hangers?

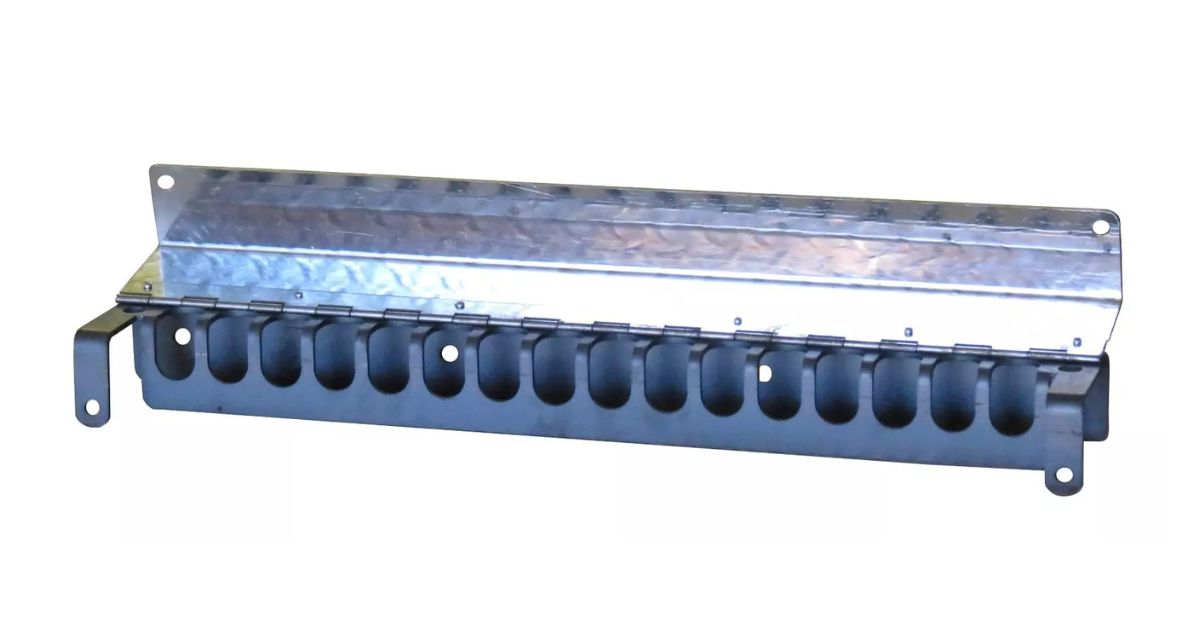

Load binder hangers are mounting systems attached to the exterior of semi-trailers. These racks hold chain binders, also called load binders or boomers, which drivers use to tighten chains that secure cargo during transport. The hangers keep these heavy metal tools within easy reach while protecting them from loss or damage during transit.

Most load binder hangers mount to the side of a trailer, though some attach to the rear doors or undercarriage. They come in various configurations depending on how many binders you need to store and how you prefer to access them. Some designs hold binders vertically, while others position them horizontally along the trailer’s length.

Why Load Binder Hangers Are Important

Professional haulers face constant pressure to load and unload quickly. When your chain binders sit in an organized, dedicated space, you save time on every job. You won’t waste minutes hunting through a cluttered cab or digging through a toolbox. Instead, you grab what you need and get back to work.

Load binder hangers also protect your investment. Chain binders aren’t inexpensive and replacing lost or damaged equipment cuts into your bottom line. A quality hanger system keeps these tools secure during transit, preventing them from bouncing around or falling off during highway speeds. This protection extends the life of your equipment and reduces replacement costs.

Safety matters too. Loose chain binders pose serious hazards. They can shift during transport and cause accidents, or they might fall onto the roadway and endanger other drivers. Proper storage eliminates these risks and helps you maintain DOT compliance during inspections.

Factors To Consider When Choosing Load Binder Hangers

Several key factors determine which load binder hanger works best for your operation. Think about how many binders you typically carry. Flatbed haulers moving heavy machinery might need racks that hold eight or more binders, while dry van operators might only need space for two or three.

Consider your access patterns. Do you need to reach your binders from ground level, or will you be accessing them from the trailer deck? Side-mounted hangers offer easy ground-level access, while rear-mounted options work well if you primarily load and unload from the back of the trailer.

Your trailer configuration matters too. Some trailers have limited mounting space due to toolboxes, landing gear, or other accessories. Measure your available mounting area before selecting a hanger system. You’ll want to verify that the rack won’t interfere with other equipment or create clearance issues.

Budget plays a role, though you should never sacrifice quality for a lower price. Cheap hangers might save money upfront, but they’ll cost you more through frequent replacements, lost equipment, and wasted time dealing with failures on the road.

Load Binder Hanger Materials

Steel dominates the load binder hanger market, and for good reason. Heavy-duty steel construction withstands the constant vibration, weather exposure, and rough handling that comes with over-the-road hauling. The best steel hangers feature powder-coated finishes that resist rust and corrosion, even in harsh climates.

Aluminum hangers offer a lighter alternative. These racks reduce overall trailer weight, which can be valuable when you’re hauling at or near weight limits. However, aluminum doesn’t match steel’s durability. You’ll need to assess whether the weight savings justify the potential for shorter service life.

Some manufacturers use stainless steel for premium applications. Stainless steel resists corrosion better than coated steel and maintains its appearance longer. The extra cost makes sense if you operate in coastal areas or regions where roads see heavy salt treatment during winter months.

Welded construction beats bolted assemblies in most cases. Welds create stronger joints that won’t loosen over time from road vibration. Look for clean, consistent welds without gaps or visible defects. These details indicate quality manufacturing that translates to reliable performance.

Load Binder Hanger Styles

Vertical hangers position binders upright against the trailer side. This style works well when mounting space runs narrow but extends high enough to accommodate the binder’s length. Vertical configurations keep binders compact and out of the way, though they may require reaching higher to access stored equipment.

Horizontal racks space binders along the trailer’s length. This arrangement makes grabbing a binder quick and easy, especially when you’re working at ground level. Horizontal hangers need more linear mounting space but offer excellent accessibility for operators who value speed.

Multi-tier designs stack storage levels to maximize capacity in limited space. These systems might hold binders on two or three levels, letting you store more equipment without extending the rack’s footprint. Multi-tier hangers suit operations that regularly use numerous binders and can’t afford to dedicate extensive trailer real estate to storage.

Integrated systems combine load binder storage with other tool racks or equipment holders. These all-in-one solutions help organize multiple accessories in a coordinated layout. They work particularly well for specialized hauling operations that need dedicated storage for various securing and safety equipment beyond just chain binders.

Load Binder Hanger Weight Capacity

Chain binders vary in size and weight. Smaller binders might weigh five pounds, while heavy-duty models tip the scales at fifteen pounds or more. Multiply that by the number of binders you carry, then add a safety margin. Your chosen hanger system must handle this combined weight without bending, sagging, or pulling away from its mounting points.

Quality manufacturers clearly rate their products for specific weight capacities. Never exceed these ratings, even if the rack looks sturdy enough to handle extra load. Exceeding capacity risks catastrophic failure that could damage your trailer, destroy your equipment, or worse, cause an accident.

The mounting system bears just as much responsibility as the rack itself. Heavy-duty bolts, properly sized for the application, distribute weight across multiple points. Some premium hangers include reinforced mounting plates that spread loads across larger areas of the trailer surface, reducing stress concentration at any single point.

Test your loaded rack before hitting the road. Give it a firm shake to check for movement or loose connections. Inspect mounting bolts for proper tightness. These quick checks take seconds but can prevent serious problems down the highway.

Keep Your Equipment Secure and Accessible

Choosing the right load binder hanger transforms how you work. You’ll secure your equipment, protect your vehicle, and maintain a cleaner, more professional trailer appearance. These benefits quickly accumulate when handling multiple weekly loads.

Star Fabrication specializes in chain binder storage solutions designed for real-world hauling conditions. Our racks combine robust construction with practical designs that keep your equipment organized and ready. When you need reliable storage that matches the demands of professional hauling, our load binder hangers deliver the quality and functionality that keep you moving efficiently mile after mile. Browse our selection to learn more.

No comments yet.