Lighting is essential for truck drivers and fleet operators. The right lighting setup means you’re not just following regulations—you’re investing in safety, professionalism, and the reputation of your business. With lighting violations being a common source of fines and roadside delays, it’s worth understanding how to prevent them. This guide walks you through practical steps to keep your rig compliant and your routes disruption-free.

Read on to learn how to prevent semi-truck lighting violations, set up your inspections, and use modern solutions like swing-out and pull-out light arms to upgrade your fleet’s visibility and reliability.

The Essentials of Semi-Truck Lighting Requirements

Semi-trucks use lights for much more than shining a path forward. Every light on your rig plays an active role in communication and safety. Here’s an overview of what’s required:

Key Types of Lighting

- Headlights illuminate the road ahead.

- Taillights signal your presence from behind.

- Brake lights signal braking to drivers behind you.

- Turn signals show intentions to change direction or turn.

- Side marker lights outline the length and presence of the truck, especially at night or in low visibility.

- Reflectors and truck extension light arms are used frequently for oversized or extended loads.

Understanding Regulations and Standards

Regulations spell out exactly what kind of lights you should have, their placement, and the color each must display. These details aren’t just for show; failing to meet these requirements can lead to:

- Fines and operational delays

- Point deductions on CMV inspections

- Increased accident risk for you and other road users

Common violations include missing side markers, non-functioning brake lights, damaged or faded reflectors, and improper colors for specific lights. Knowing the rules is your first defense against fines and downtime.

Regular Inspection and Maintenance

Lighting systems take a beating on the road, so routine inspections are necessary. Reliable lighting starts with good habits, not luck.

Visual Check

Walk around your truck and trailer. Look for broken lenses, burned-out bulbs, or lenses clouded with dirt and grime.

Functional Test

Turn on your truck and activate all lights, including brake and hazard lights. Ask a coworker to confirm all lights are working, or use reflective surfaces if you’re alone.

Check for Secure Mounting

Light fixtures and arms should be firmly attached. Wiggle each one gently to make sure nothing is loose or hanging.

Review Wiring

Look underneath for any exposed, frayed, or corroded wiring. Damaged wiring is a leading cause of lighting failures and violations.

Tips for Replacing Parts

- Carry spare bulbs and fuses for your typical lighting setup.

- Consider keeping a portable toolkit for easy lens replacement or tightening jobs.

- For more complex issues, consult your fleet’s maintenance manager or a professional technician.

By setting a regular inspection schedule that includes daily walkarounds and weekly in-depth checks, you reduce the risk of being caught out by preventable lighting violations.

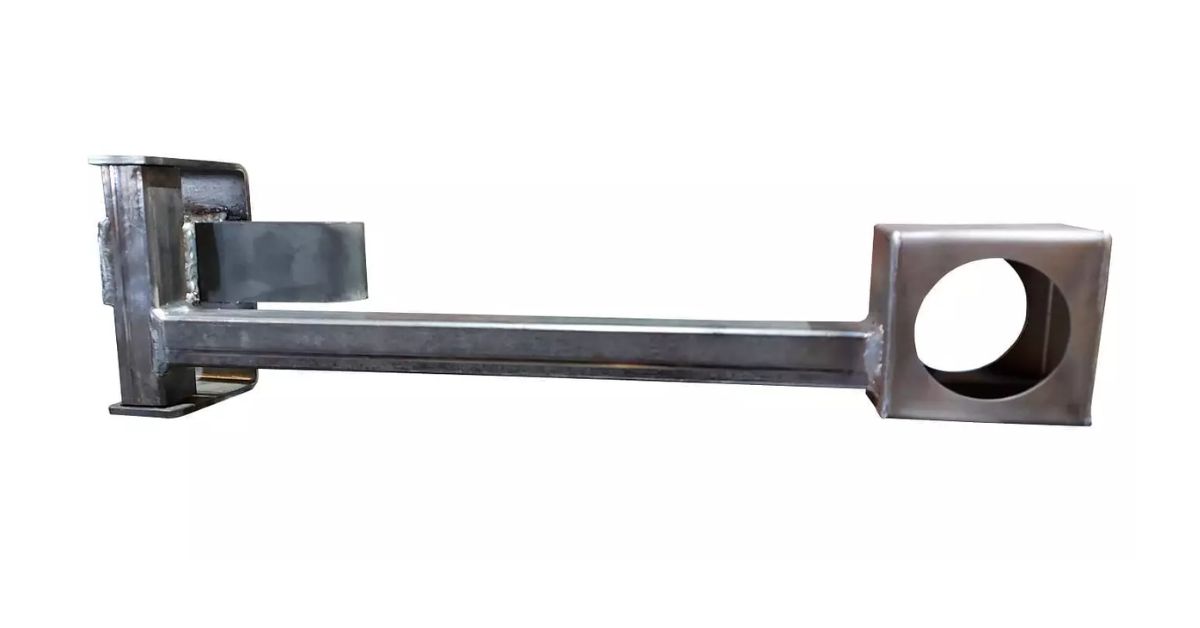

Swing-Out and Pull-Out Light Arms for Oversized Loads

If you haul oversized or wide loads, lighting requirements get more complicated—but so does the solution set. Swing-out and pull-out light arms, like those from Star Fabrication Limited, are designed for these challenges.

Why Use Truck Extension Light Arms?

Oversized loads often extend beyond the regular placement of trailer lights. Truck extension light arms reposition your lights outward, making your truck’s width clear to everyone on the road. Here’s what makes them stand out:

- Enhanced visibility: Your load edges are well-lit and visible, day or night.

- Stable and secure: Spring-loaded and pull-out designs keep lights firmly in place, even on rough roads.

- Adaptable: Truck extension light arms are suitable for different trailer widths and types of oversized cargo.

Types of Light Arms You Can Use

- Spring-loaded swing-out light arms: Quick to deploy and stow, ideal for temporary oversized loads

- Light arms with light boxes: Integrated light boxes protect fixtures and wiring from weather and road debris

- Extra-long light arms: Extend farther out for extremely wide loads

- Aluminum pull-out light arms: Lightweight yet durable, easy to maneuver, and built for longevity

Solutions like the ones from Star Fabrication are engineered for effortless operation and durability, ensuring you can adapt your lighting to different cargos without sacrificing safety or racking up violations.

The Best Practices for Lighting Compliance

A little attention to detail goes a long way. Following these best practices helps ensure all your truck’s lights are compliant and ready for the long haul.

Maintain Proper Wiring and Connections

- Shield wires from road debris and water exposure.

- Regularly inspect wiring for wear; replace corroded or loose connectors.

- Use weather-resistant connectors when possible.

Use Reflective Tape and Conspicuity Materials

- Reflective tape isn’t just a backup for electronic lights; it adds another layer of visibility, especially from awkward angles.

- Apply tape evenly along the trailer sides and rear in the placements required by regulations.

Keep Lenses and Reflectors Clean

Dust, mud, and salt obscure lights and reduce their effectiveness. During your inspection, clean each lens with a soft cloth and watch for cracks or dulling.

Choose Durable Fixtures and Light Arms

Invest in sturdy extension light arms for those regularly handling oversized or wide loads. Look for features like:

- Spring-loaded mechanisms (for stability)

- Aluminum construction (for corrosion resistance and easy handling)

- Integrated light boxes (for extra protection)

With products like swing-out and pull-out extensions from Star Fabrication Limited, you remove much of the guesswork and make sure your lighting setup adapts to your route and cargo.

Staying Road-Ready With Reliable Lighting

Truck lighting isn’t just a checklist item or another regulation to tick off. It’s an ongoing commitment to safety, operational efficiency, and professional reputation. By understanding how to prevent semi-truck lighting violations, setting up steady inspection routines, and investing in the right equipment, you set your fleet up for reliable, disruption-free journeys.

If you frequently deal with oversized loads, look at swing-out and pull-out light arms from Star Fabrication Limited. Our range of durable, adaptable light extensions helps you meet regulations and avoid the headaches of preventable violations. Don’t leave your next trip up to chance; equip your rig with the best tools available and stay on top of lighting compliance every mile of the way.

For more tips and reliable lighting solutions, check out the truck extension light arms available from Star Fabrication Limited. Your next inspection will go smoother, and you’ll be able to enjoy greater peace of mind.

No comments yet.